Product Description

Product Description

|

Products |

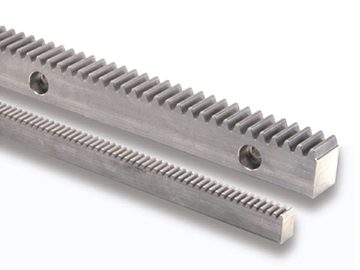

Gear rack |

|||

|

Precision grade |

DIN5, DIN6, DIN7, DIN8, DIN10 |

|||

|

Material |

C45 steel, 304SS, 316SS, 40CrMo, nylon, POM |

|||

|

Heat treatment |

High frequency,Quenching/Carburization, Teeth hardened |

|||

|

Surface treatment |

Zinc-plated,Nickle-plated,Chrome-plated,Black oxide or as you need |

|||

|

Application Machine |

Precision cutting machines. Lathes machine Milling machines Grinders machine Automated mechanical systems Automated warehousing systems. |

|||

|

Produce Machine |

CNC engine lathe CNC milling machine CNC drilling machine CNC grinding machine CNC cutting machines Machining center |

|||

|

Workstyle |

Execution is more preferred than empty talk. |

|||

|

Stock Gear Rack Type |

Specification |

Color |

|

Helical gear rack |

M1 15*15*1000mm |

White |

|

M1.5 19*19*1000mm |

White |

|

|

M2 24*24*1000mm |

White |

|

|

M3 29*29*1000mm |

White |

|

|

M4 39x39x1000mm |

White |

|

|

Spur gear rak |

M1 15*15*1000mm |

Black |

Rack Assembly

To assemble connected racks more smoothly, 2 ends of a standard rack would add half tooth which is convenient for next half tooth of next rack to be connected to a complete tooth. The following drawing shows how 2 racks connect and tooth gauge can control pitch position accurately.

With regards to connection of helical racks, it can be connected accurately by opposite tooth gauge.

1. When connecting racks, we recommend lock bores on the sides of rack first, and lock bores by the sequence of the foundation. With assembling the tooth gauge, pitch position of racks can be assembled accurately and completely.

2. Last, lock the position pins on 2 sides of rack; the assembly is completed.

Test

Use Coordinate Measuring Machine to test the precision and hardness of gear rack and pinion

Packaging & Shipping

Small quantity: We will use carton box.

Big quantity: We will use wooden cases.

Company Profile

ZheJiang Haorongshengye Electrical Equipment Co., Ltd.

1. Was founded in 2008

2. Our Principle:

“Credibility Supremacy, and Customer First”

3. Our Promise:

“High quality products, and Excellent Service”

4. Our Value:

“Being Honesty, Doing the Best, and Long-lasting Development”

5. Our Aim:

“Develop to be a leader in the power transmission parts industry in the world”

|

6.Our services: |

1).Competitive price |

|||

|

2).High quality products |

||||

|

3).OEM service or can customized according to your drawings |

||||

|

4).Reply your inquiry in 24 hours |

||||

|

5).Professional technical team 24 hours online service |

||||

|

6).Provide sample service |

||||

Main products

Machines

Exbihition

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can spur gear racks be customized for specific machinery and equipment?

Yes, spur gear racks can be customized to meet the specific requirements of different machinery and equipment. The versatility and flexibility of spur gear racks allow for customization in various aspects, enabling their seamless integration into specific applications. Here’s how spur gear racks can be customized:

Size and Dimension: Spur gear racks can be manufactured in different sizes and dimensions to suit the space constraints and design specifications of specific machinery and equipment. The length, width, and height of the rack can be adjusted to ensure optimal fit and compatibility within the system. Customizing the size and dimension of the rack allows for efficient utilization of available space and seamless integration into the mechanical assembly.

Material Selection: Spur gear racks can be made from different materials depending on the application requirements. Common materials include steel, stainless steel, cast iron, and various alloys. The choice of material depends on factors such as load capacity, durability, corrosion resistance, and operating conditions. Customizing the material selection ensures that the spur gear rack is suitable for the specific machinery or equipment, considering factors such as environmental conditions, weight constraints, and mechanical stresses.

Tooth Profile: The tooth profile of a spur gear rack can be customized to optimize its performance for specific applications. Different tooth profiles, such as involute, cycloidal, or modified profiles, can be employed to achieve specific characteristics like smooth engagement, reduced noise, or increased load capacity. The selection of the tooth profile is tailored to the requirements of the machinery or equipment, ensuring optimal performance and longevity.

Pressure Angle: The pressure angle, which defines the angle between the line of action and the line perpendicular to the tooth surface, can be customized for spur gear racks. By selecting an appropriate pressure angle, the gear’s efficiency, load distribution, and contact strength can be optimized for specific machinery and equipment. Customizing the pressure angle helps in achieving the desired mechanical properties and performance of the spur gear rack.

Surface Treatment: Spur gear racks can undergo various surface treatments to enhance their performance and durability. Surface treatments such as heat treatment, case hardening, coating, or plating can be applied to improve wear resistance, corrosion resistance, and reduce friction. Customizing the surface treatment ensures that the spur gear rack can withstand the specific operating conditions and environmental factors it will encounter in the machinery or equipment.

Gear Ratio: The gear ratio between the spur gear rack and the mating pinion gear can be customized to achieve the desired linear motion or power transmission characteristics. By adjusting the number of teeth on the rack and the pinion gear, the gear ratio can be tailored to the specific requirements of the machinery or equipment. Customizing the gear ratio allows for precise control of linear motion or adapting power transmission to meet the desired speed and torque requirements.

By considering these customization options, spur gear racks can be tailored to match the unique needs of different machinery and equipment. Customization ensures that the spur gear rack integrates seamlessly with the overall mechanical system, enhances performance, and contributes to the overall efficiency and reliability of the machinery or equipment.

How do spur gear racks handle variations in rack length and width?

Spur gear racks are designed to accommodate variations in rack length and width, allowing for flexibility in different applications. The design and construction of spur gear racks incorporate features that enable easy adjustment and adaptation to different rack dimensions. Here’s a detailed explanation of how spur gear racks handle variations in rack length and width:

- Modular Design: Spur gear racks often utilize a modular design, where individual rack segments can be combined or extended to achieve the desired length. These rack segments typically have standardized dimensions and tooth profiles, allowing for easy customization and assembly. By connecting multiple rack segments, the overall length of the gear rack can be adjusted to suit specific requirements. This modular approach provides flexibility and scalability in accommodating variations in rack length.

- Mounting and Fastening Options: Spur gear racks are designed with various mounting and fastening options to accommodate variations in rack width. They may feature multiple mounting holes, slots, or T-slots along the rack’s length, allowing for different attachment methods. This enables the gear rack to be securely mounted and aligned with other components, regardless of the specific width or spacing requirements of the application. These mounting options provide versatility in handling variations in rack width.

- Customization and Machining: In cases where standard rack dimensions do not meet specific requirements, spur gear racks can be customized and machined to the desired length and width. Manufacturers can fabricate gear racks according to specific design specifications, tailoring them to the application’s exact needs. This customization may involve cutting the rack to the required length, modifying the tooth profile, or adjusting the width through machining processes. Customization options allow spur gear racks to handle variations beyond standard dimensions.

- Adjustable Guides and Supports: To handle variations in rack length, gear racks can incorporate adjustable guides and supports. These guides and supports can be positioned along the rack’s length to provide additional stability and ensure proper engagement with the pinion gear. By adjusting the position of these guides and supports, the gear rack can be effectively supported and aligned, even when the rack length varies. This ensures smooth and accurate motion transmission along the entire length of the rack.

- Flexible Couplings: In applications where variations in rack length or alignment occur due to thermal expansion, misalignment, or other factors, flexible couplings can be utilized. Flexible couplings compensate for small angular and parallel misalignments between the driving and driven shafts. By incorporating flexible couplings in the gear rack system, any variations or misalignments in rack length can be accommodated, allowing for smooth and efficient power transmission.

In summary, spur gear racks handle variations in rack length and width through modular design, mounting and fastening options, customization and machining, adjustable guides and supports, and the use of flexible couplings. These features provide the necessary flexibility, adaptability, and precision required to accommodate different rack dimensions and ensure optimal performance in various applications.

Can you explain the purpose and applications of spur gear racks in machinery?

Spur gear racks serve various purposes and find widespread applications in machinery across different industries. They are commonly used for the conversion of rotational motion into linear motion or vice versa. Here are some key purposes and applications of spur gear racks:

Motion Conversion: One of the primary purposes of spur gear racks is to convert rotational motion into linear motion. By meshing with a pinion gear, the teeth on the rack translate the rotational movement of the pinion into a linear movement along the length of the rack. This linear motion can be utilized to drive various mechanisms and components in machinery.

Positioning and Precision: Spur gear racks are often employed for precise positioning tasks in machinery. The linear motion provided by the rack allows for accurate movement and positioning of components, tools, or workpieces. This is particularly useful in applications such as CNC machines, where precise positioning is critical for machining operations.

Power Transmission: Spur gear racks are used to transmit power between different components in machinery. By incorporating a pinion gear that meshes with the rack, rotational motion can be transferred from one part of the machinery to another. This enables the transmission of power to drive various mechanisms, such as conveyors, lifts, or other linear motion systems.

Steering Systems: Spur gear racks play a crucial role in rack and pinion steering systems, commonly used in automobiles and other vehicles. The rotational motion of the steering wheel is converted into linear motion through the interaction between the pinion gear and the rack. This allows for precise control of the vehicle’s steering, enabling the driver to navigate and maneuver the vehicle.

Linear Actuators: Spur gear racks are utilized in linear actuator systems to generate linear motion for pushing, pulling, or positioning loads. The rack and pinion configuration provides a simple and efficient method for converting rotational motion into linear motion. Linear actuators employing spur gear racks are used in various applications, including robotics, industrial automation, and machinery positioning systems.

Machine Tools: In machine tools such as milling machines, lathes, and drilling machines, spur gear racks are employed for precise movement and positioning of cutting tools or workpieces. The linear motion provided by the rack enables controlled and accurate machining operations, contributing to the overall performance and quality of the machined parts.

Automation and Robotics: Spur gear racks are widely used in automation and robotics systems. They facilitate linear motion for the movement of robotic arms, conveyors, and other automated mechanisms. The precise and controlled motion offered by spur gear racks is instrumental in achieving accurate and repeatable operations in automated processes.

Industrial Machinery: Spur gear racks find applications in various industrial machinery, including packaging machines, printing presses, textile machinery, material handling systems, and more. They contribute to the efficient and reliable operation of these machines by providing linear motion, power transmission, and precise positioning capabilities.

Overall, spur gear racks play a vital role in machinery, enabling linear motion, precise positioning, power transmission, and automation. Their versatility and reliability make them a fundamental component in numerous applications across diverse industries.

editor by Dream 2024-05-09