Product Description

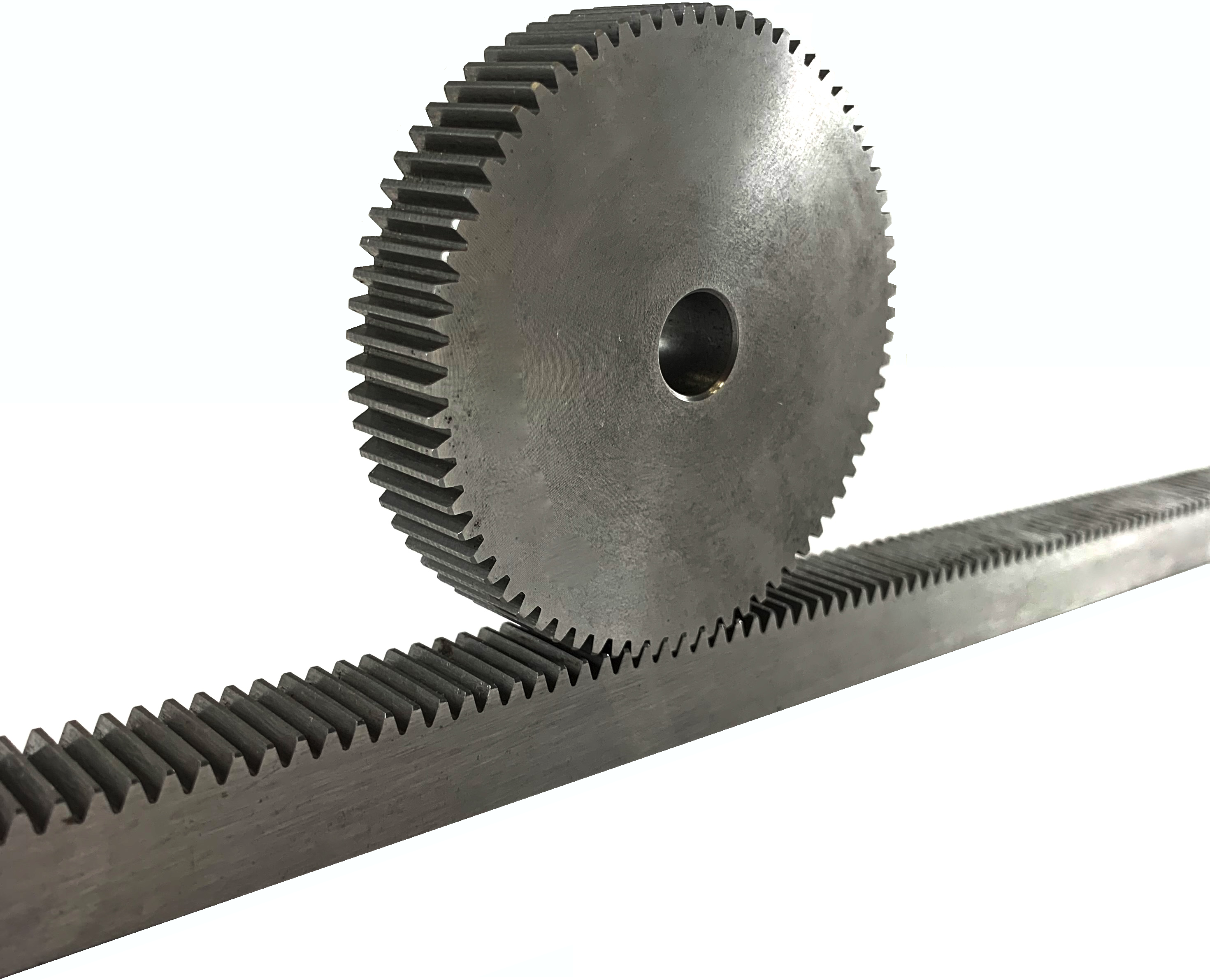

Gear And Rack Pinion

Product Description

| Model number | M1-M12 |

| Material | Brass, C45 steel,Stainless steel,Copper,POM,Aluminum,Alloy and so on |

| Surface treatment | Zinc plated, Nickel plated, Passivation, Oxidation, Anodization, Geomet, Dacromet, Black Oxide, Phosphatizing, Powder Coating and Electrophoresis, etc |

| Standard | ISO, DIN, ANSI, JIS, BS and Non-standard. |

| Precision | DIN6,DIN7,DIN8,DIN9. |

| Teeth treatment | Hardened,Milled or Ground |

| Tolerance | 0.001mm-0.01mm-0.1mm |

| Finish | shot/sand blast, heat treatment, annealing, tempering, polishing, anodizing, zinc-plated |

Packaging & Shipping

Packaging Details:

1)Sample order packing by paper carton for saving freight charge;

2)bulk order sent by sea will be packed by film and wooden carton.

3) as customer’s requirements.

Company Profile

Company Information:

ZheJiang SAIR MECHANICAL XIHU (WEST LAKE) DIS. CO.,LTD

ZheJiang Sair Mechanical Xihu (West Lake) Dis. Co., Ltd, which is mainly responsible for the production, 1 of the largest linear guide and ball screw manufacturer in China. With strong technical strength, advanced production equipments, and perfect after-sale services, our company is the leading precision machinery manufacturer, which have research and development, manufacturing, sales, service all in one. Our high-quality products are not only popular all over the country, but also exported to Europe, Americas, Southeast Asia, Africa etc. , totally more than 70 countries globally. Our products have good performance and are highly trusted and admired by all the domestic & overseas customers.

FAQ

1. Q: How about the quality of your product?

A: 100% inspection during production.

Our products are certified to ISO9001-2008 international quality standards.

2. Q: What’s the delivery time?

A: For custom order, within 2000 meters,

Production time is 15days after confirmed every details.

3. Q: What’s your packing?

A: Our Normal packing is bulking in PE bag, and then into plywood Cartons.

We also can pack products according to your requirement.

4. Q: What about the warranty?

A: We are very confident in our products,

and we pack them very well to make sure the goods in well protection.

5.Q: Could you send me your catalogue and price list?

A: As we have more than hundreds of products,

it is really too hard to send all of catalogue and price list for you.

Please inform us the style you interested, we can offer the pricelist for your reference.

6.Q:There are a lot of companies which export bearings, why do you choose us?

A: As we are a genuine linear guide supplier since 2011.and we are really factory, you need not pay the profit for middlemen.

so we can offer you the lowest and competitive price .

Thanks for your valuable time 🙂

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Samples: |

US$ 6/Piece

1 Piece(Min.Order) | Order Sample not free

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does the design of a spur gear rack affect its performance?

The design of a spur gear rack plays a crucial role in determining its performance characteristics and overall functionality. Various design elements and parameters influence the performance of a spur gear rack. Here’s how the design aspects affect its performance:

- Tooth Profile: The tooth profile of the spur gear rack, such as involute or cycloidal, directly impacts its performance. The tooth profile affects the smoothness of tooth engagement, the load distribution along the tooth contact area, and the amount of backlash or clearance between mating gears. A well-designed tooth profile ensures efficient power transmission, minimizes noise and vibration, and maximizes the contact area for improved load-carrying capacity.

- Pitch: The pitch of the spur gear rack refers to the distance between consecutive teeth. The pitch determines the linear motion achieved per revolution of the mating pinion gear. The design of the rack should consider the specific requirements of the application. A smaller pitch provides finer and more precise linear motion, while a larger pitch allows for faster linear motion over a given distance. The pitch selection affects the speed, accuracy, and resolution of the linear motion system.

- Pressure Angle: The pressure angle is the angle between the line of action and the line perpendicular to the tooth surface. It affects the efficiency, load distribution, and contact strength of the gear system. Common pressure angles for spur gear racks are 14.5 degrees and 20 degrees. Higher pressure angles generally offer higher load-carrying capacity and improved contact strength. The appropriate pressure angle selection depends on the specific application requirements and the desired balance between load capacity and efficiency.

- Module: The module of a spur gear rack defines the size and dimensions of the teeth. It affects the strength, load-carrying capacity, and overall size of the gear. A larger module generally results in larger teeth and a more robust gear rack capable of handling higher loads. However, it also increases the size and weight of the gear. The module selection should consider the application’s torque requirements, available space, and weight constraints to achieve an optimal balance between strength and size.

- Material: The choice of material for the spur gear rack impacts its performance and durability. Common materials used include steel, stainless steel, cast iron, and various alloys. The material selection depends on factors such as load capacity, operating conditions, and desired properties like strength, wear resistance, and corrosion resistance. The material should be carefully chosen to ensure sufficient strength and durability while considering environmental factors, temperature variations, and the presence of any corrosive substances.

- Surface Finish: The surface finish of the spur gear rack affects its performance in terms of friction, wear resistance, and noise generation. Proper surface finishing techniques, such as grinding or honing, can improve the tooth surface quality, reduce friction, and minimize noise. A smooth and properly finished tooth surface enhances the efficiency, reduces power losses, and increases the overall performance of the gear rack system.

- Tolerance and Accuracy: The design of the spur gear rack should consider the required tolerances and accuracy for the specific application. Precise manufacturing and tight tolerances ensure proper tooth engagement, minimize backlash, and maintain accurate linear motion. The design should account for factors such as tooth profile accuracy, concentricity, and parallelism to achieve the desired performance characteristics.

- Geometry and Strength: The overall geometry and strength of the spur gear rack affect its load-carrying capacity and resistance to tooth failure. The gear rack’s geometry, including tooth thickness, height, and width, should be designed to distribute the load evenly along the tooth contact area. Proper tooth geometry improves the gear’s ability to withstand high loads, reduces stress concentrations, and enhances its overall performance and longevity.

By carefully considering these design aspects, a spur gear rack can be optimized to meet the specific performance requirements of different applications. A well-designed gear rack ensures efficient power transmission, smooth operation, accurate linear motion, and reliable performance throughout its intended service life.

What materials are commonly used in the construction of spur gear racks?

In the construction of spur gear racks, several materials are commonly used to ensure strength, durability, and efficient performance. The choice of material depends on factors such as the specific application requirements, operating conditions, and budget constraints. Here are some materials commonly used in the construction of spur gear racks:

- Steel Alloys: Steel alloys, such as carbon steel and alloy steel, are widely employed in the construction of spur gear racks. These materials offer excellent strength, hardness, and wear resistance. Carbon steel, such as SAE 1045 or 1050, is commonly used for gear racks due to its high tensile strength and affordability. Alloy steels, such as 8620 or 4140, provide enhanced mechanical properties and are utilized in applications requiring higher load-carrying capacity or increased toughness.

- Stainless Steel: Stainless steel is another popular material choice for spur gear racks, especially in applications where corrosion resistance is crucial. Stainless steel alloys, such as AISI 300 series (e.g., 304 or 316), offer excellent resistance to moisture, chemicals, and atmospheric corrosion. These materials are commonly used in food processing equipment, marine applications, or environments with high humidity or exposure to corrosive substances.

- Cast Iron: Cast iron is utilized in the construction of gear racks when high strength and wear resistance are required. Gray cast iron (e.g., ASTM A48 Class 40) is commonly used due to its good machinability, damping properties, and ability to withstand heavy loads. Cast iron gear racks are often employed in industrial machinery, power transmission systems, and applications with demanding operating conditions.

- Plastics: Engineered plastics, such as nylon (polyamide) and acetal (polyoxymethylene), are used in applications where noise reduction, self-lubrication, and resistance to chemical corrosion are desirable. Plastic gear racks offer advantages such as lightweight, low friction, and the ability to run without additional lubrication. They find applications in industries like automotive, consumer electronics, and medical equipment.

- Bronze and Brass: Bronze and brass alloys are utilized in specific applications that require excellent machinability, low friction, and resistance to wear. Phosphor bronze (e.g., ASTM B139) and brass (e.g., ASTM B16) are commonly used for gear racks in applications such as musical instruments, clocks, and low-load precision machinery.

It’s important to note that the selection of the appropriate material for a spur gear rack depends on various factors, including the specific application requirements, load conditions, operating temperatures, and environmental factors. Engineers and designers consider these factors to determine the most suitable material that will provide the necessary strength, durability, and performance for the intended application.

What is a spur gear rack, and how does it function?

A spur gear rack is a type of gear mechanism that consists of a straight, flat toothed bar called a rack and a cylindrical gear called a pinion. It is commonly used in various mechanical systems to convert rotational motion into linear motion or vice versa.

The rack is a long, straight bar with teeth along one side. These teeth are usually straight and parallel to the rack’s axis. The pinion, on the other hand, is a small cylindrical gear with teeth that mesh with the teeth on the rack. The pinion is mounted parallel to the rack and engages with the rack by rotating against it.

The functioning of a spur gear rack is relatively simple. When the pinion gear rotates, its teeth engage with the teeth on the rack. As the pinion rotates, it causes the rack to move linearly along its length. This linear motion can be used to drive other mechanisms or to convert linear motion into rotational motion.

For example, in a rack and pinion steering system in automobiles, the rotation of the steering wheel is converted into linear motion of the rack. This linear motion is then used to steer the vehicle’s wheels. Similarly, in some machine tools, the linear motion of the rack is used to position a cutting tool or a workpiece.

The teeth on the rack and pinion gear are designed in a way that ensures smooth and efficient transfer of motion. The teeth mesh tightly, minimizing backlash and providing accurate and precise motion transfer. The size and shape of the teeth can vary depending on the specific application and requirements.

In summary, a spur gear rack is a gear mechanism that utilizes a straight toothed bar (rack) and a cylindrical gear (pinion) to convert rotational motion into linear motion or vice versa. It is widely used in various mechanical systems for its simplicity, efficiency, and versatility.

editor by Dream 2024-04-29