Product Description

Product Description

Bevel Gear:

1. Made in CK45 or stainless steel

2. All sizes, from M1 to M8, with different teeth

3. Bevel gear, spur gear

Bevel Gear:

1. Manufactured by HangZhou Vision Industrial Group Comany for more than 16 years.

2. Material: With CK45 or stainless steel

3. All sizes, from M1 to M8, with different teeth

4. All kinds of gears, bevel gear, spur gear, spiral gear, helical gear, double helical gear

5. Customized gear

6. Welcome your inquiry

Detailed Photos

Product Parameters

Our Advantages

Packaging & Shipping

WHY CHOOSE US

Comprehensive Product Portfolio We produce and supply a wide range of power transmission

products including drive chains, leaf chains, conveyor chains, agricultural chains, sprockets, and

couplings. This one-store-for-all shopping experience will significantly reduce your searching costs while

guarantee youfind what you want at 1 click.

Value Choice Products Our products are the best combination of quality and price, and you get what

you want within your budgets

Seasoned Sales Associates and Engineers We have 15 seasoned sales associates and 5 engineers;

on our team at your disposal any time when you need a helping hand. They are well trained with industry

know-now and will always respond to your requests within 24 hours.

100% Customer Retention Rate Our regular customers from overseas come back not just for our

premium quality products, but for the superior services that we’ve provided over the years

FAQ

Q1: What’s your average lead time?

A: It varies. Our regular end-to-end lead time is 1-2 months.. We also provide express shipments for rush orders. For details,please consult our sales associate.

Q2: Is your price better than your competitors given the same quality?

A: Definitely YES. We provide the most competitive price in the power transmission industry. If price disparity exists, we’ll be more than happy to do a price match.

Q3: Can you make chains according to my CAD drawings?

A: Yes. Besides the regular standard chains, we produce non-standard and custom-design products to meet the specific technical requirements. In reality, a sizable portion of our production capacity is assigned to make non-standard products.

Q4: Can we inspect the goods before shipment?

A: Yes. You or your representative or any third-party inspection party assigned is allowed access to our facility and do the inspection.

Q5: What kind of payment method is acceptable for your mill?

A: We’re flexible. We take T/T, L/C, or any other online payment methods so long as it’s applicable for you.

Q6: What if I have any other questions?

A: Whenever in doubt, you’re always encouraged to consult our sales associate any time – They will help you to your satisfaction.

| Application: | Motor, Machinery, Marine, Agricultural Machinery |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | External Gear |

| Manufacturing Method: | Cut Gear |

| Toothed Portion Shape: | Bevel Wheel |

| Material: | 45c Steel |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

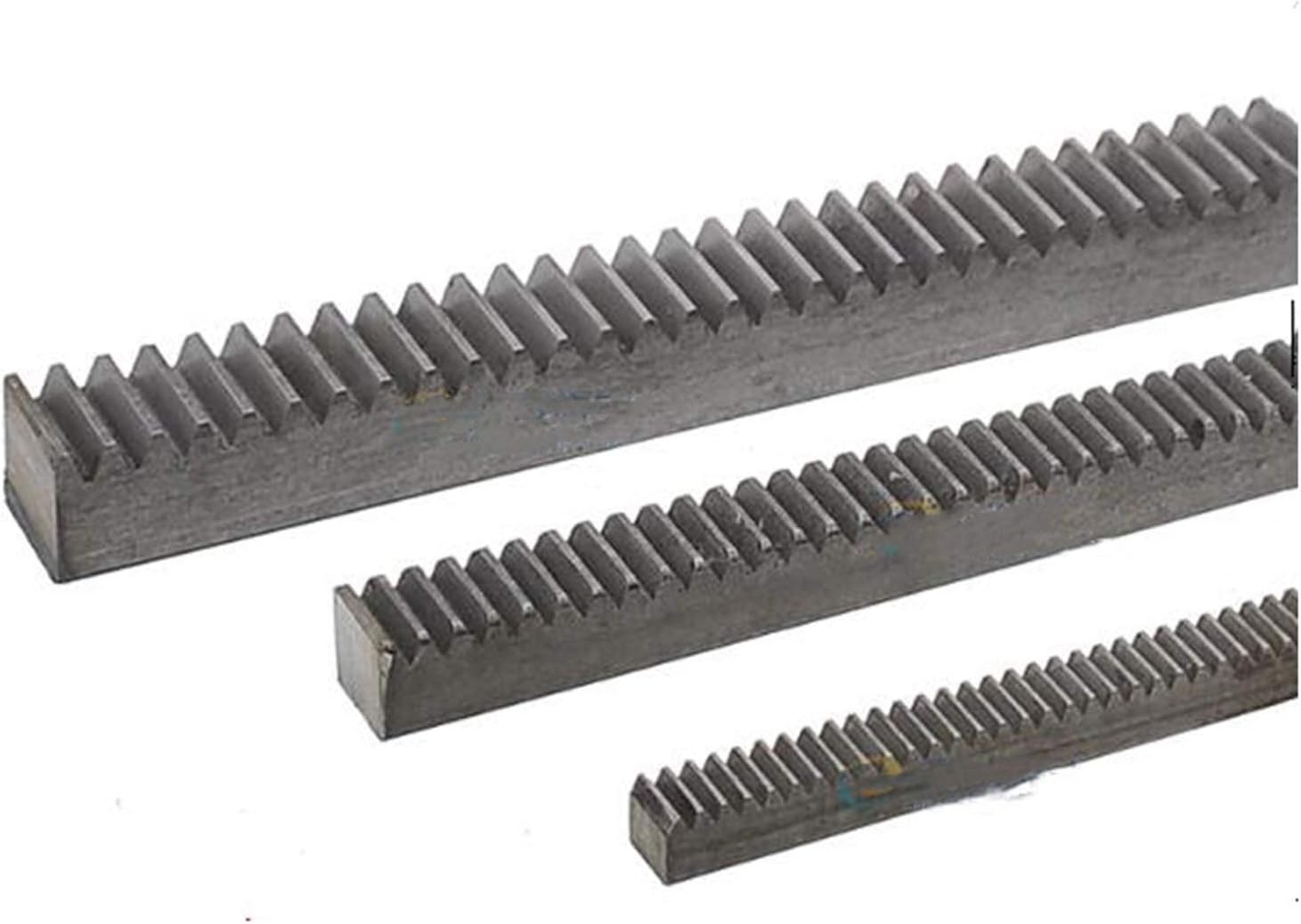

What safety considerations should be kept in mind when working with spur gear racks?

When working with spur gear racks, it is important to keep several safety considerations in mind to ensure the well-being of personnel and the proper functioning of the equipment. Here are some key safety considerations to be aware of:

- Entanglement and Pinch Points: Spur gear racks have rotating parts and moving components. It is crucial to be cautious of entanglement and pinch points during installation, operation, and maintenance. Keep hands, clothing, and other loose items away from the gear rack and associated machinery while it is in motion. Use appropriate guards or protective covers to prevent accidental contact with the gears and rotating parts.

- Lubrication and Maintenance: Proper lubrication is essential for the smooth operation of spur gear racks. Follow the manufacturer’s guidelines regarding the type and amount of lubricant to be used. Regularly inspect and maintain the gear rack system to ensure that it remains in good working condition. Replace worn-out or damaged components promptly to prevent potential hazards and maintain optimal performance.

- Load Capacity and Overloading: Spur gear racks have specific load capacities that should not be exceeded. It is important to understand the load limits of the gear rack and ensure that the equipment or machinery it is integrated with operates within those limits. Overloading can lead to premature wear, tooth failure, and potential accidents. Refer to the manufacturer’s specifications and guidelines to determine the appropriate load capacity for the gear rack.

- Proper Installation: Ensure that the spur gear rack is correctly installed according to the manufacturer’s instructions. Improper installation can result in misalignment, which may cause excessive wear, noise, and reduced performance. Follow proper alignment procedures and use appropriate tools and techniques to secure the gear rack in place. If unsure, consult with a qualified professional or the manufacturer for guidance.

- Noise and Vibration: Spur gear racks can generate noise and vibration during operation. Excessive noise and vibration may indicate issues such as misalignment, inadequate lubrication, or worn-out components. Regularly monitor the gear rack system for unusual noise or excessive vibration and promptly investigate and address any potential problems to avoid safety hazards and equipment failure.

- Training and Awareness: Ensure that personnel working with spur gear racks receive appropriate training and instructions on safe operating procedures. Familiarize them with the potential hazards associated with gear rack systems and educate them on how to safely perform tasks such as maintenance, inspection, and troubleshooting. Encourage a safety-conscious culture and promote awareness of potential risks.

- Emergency Stop and Shutdown: Make sure that the equipment or machinery integrated with the spur gear rack has emergency stop mechanisms in place. Clearly label and identify emergency stop buttons or switches and ensure that personnel know their locations and how to use them. Regularly test the emergency stop function to verify its effectiveness. In case of any abnormalities or emergencies, immediately initiate the shutdown procedure and follow appropriate safety protocols.

- Protective Equipment: When working with spur gear racks, it is advisable to wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and protective clothing. PPE can provide an additional layer of protection against potential hazards, such as flying debris, sharp edges, or accidental contact with moving parts.

These safety considerations are essential for maintaining a safe working environment when dealing with spur gear racks. By following proper safety practices, personnel can minimize the risk of accidents, ensure the longevity of the equipment, and promote a culture of safety within the workplace.

How do spur gear racks handle variations in environmental conditions?

Spur gear racks are designed to handle variations in environmental conditions and maintain their performance and durability. They are engineered to withstand factors such as temperature fluctuations, moisture, dust, and other environmental challenges. Here’s a detailed explanation of how spur gear racks handle variations in environmental conditions:

- Material Selection: The choice of materials for spur gear racks is crucial in ensuring their resilience to environmental conditions. Common materials used for gear racks include steel alloys, stainless steel, and engineered plastics. These materials offer high strength, corrosion resistance, and thermal stability, enabling gear racks to withstand environmental challenges effectively.

- Surface Treatments: Spur gear racks can undergo surface treatments to enhance their resistance to environmental conditions. For example, gear racks can be coated or plated with materials such as zinc, nickel, or chrome to provide corrosion resistance and improve durability. These surface treatments form a protective barrier, safeguarding the gear racks from moisture, chemicals, and abrasive particles.

- Lubrication: Proper lubrication is essential for the smooth operation and longevity of spur gear racks, especially in varying environmental conditions. Lubricants reduce friction, prevent wear, and protect against corrosion. The selection of appropriate lubricants depends on the operating conditions and environmental factors. In extreme environments, specialized lubricants with high viscosity or additives may be used to ensure optimal gear rack performance.

- Sealing and Enclosure: Spur gear racks can be enclosed or sealed to protect them from environmental elements. Seals and enclosures prevent the ingress of moisture, dust, and contaminants, preserving the integrity and performance of the gear racks. Various sealing methods, such as gaskets, O-rings, or lip seals, can be employed to create a barrier against external elements.

- Heat Dissipation: Temperature variations can impact the performance of gear racks, especially in high-temperature environments. Proper heat dissipation mechanisms, such as cooling fans, heat sinks, or ventilation, can be incorporated to regulate the temperature and prevent overheating. Efficient heat dissipation helps maintain the dimensional stability of gear racks and prevents premature wear or distortion.

- Design Considerations: Gear rack designs can incorporate features that enhance their resilience to environmental conditions. For example, the inclusion of debris guards, labyrinth seals, or protective covers can prevent the accumulation of dirt, dust, or foreign particles. Additionally, gear rack designs can incorporate drainage channels or provisions for moisture egress to mitigate the effects of moisture and humidity.

- Maintenance and Inspection: Regular maintenance and inspection practices are essential to ensure the optimal performance of spur gear racks in varying environmental conditions. Periodic cleaning, lubrication replenishment, and visual inspections help identify any signs of wear, damage, or degradation caused by environmental factors. Timely maintenance and necessary repairs or replacements can prolong the lifespan of gear racks.

By employing suitable materials, surface treatments, lubrication practices, sealing mechanisms, and design considerations, spur gear racks can effectively handle variations in environmental conditions. It is crucial to consider the specific environmental challenges that gear racks may encounter in a particular application and apply appropriate measures to enhance their resilience and longevity.

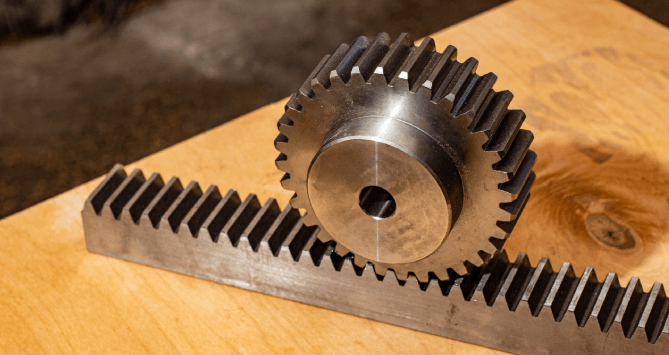

Can you explain the purpose and applications of spur gear racks in machinery?

Spur gear racks serve various purposes and find widespread applications in machinery across different industries. They are commonly used for the conversion of rotational motion into linear motion or vice versa. Here are some key purposes and applications of spur gear racks:

Motion Conversion: One of the primary purposes of spur gear racks is to convert rotational motion into linear motion. By meshing with a pinion gear, the teeth on the rack translate the rotational movement of the pinion into a linear movement along the length of the rack. This linear motion can be utilized to drive various mechanisms and components in machinery.

Positioning and Precision: Spur gear racks are often employed for precise positioning tasks in machinery. The linear motion provided by the rack allows for accurate movement and positioning of components, tools, or workpieces. This is particularly useful in applications such as CNC machines, where precise positioning is critical for machining operations.

Power Transmission: Spur gear racks are used to transmit power between different components in machinery. By incorporating a pinion gear that meshes with the rack, rotational motion can be transferred from one part of the machinery to another. This enables the transmission of power to drive various mechanisms, such as conveyors, lifts, or other linear motion systems.

Steering Systems: Spur gear racks play a crucial role in rack and pinion steering systems, commonly used in automobiles and other vehicles. The rotational motion of the steering wheel is converted into linear motion through the interaction between the pinion gear and the rack. This allows for precise control of the vehicle’s steering, enabling the driver to navigate and maneuver the vehicle.

Linear Actuators: Spur gear racks are utilized in linear actuator systems to generate linear motion for pushing, pulling, or positioning loads. The rack and pinion configuration provides a simple and efficient method for converting rotational motion into linear motion. Linear actuators employing spur gear racks are used in various applications, including robotics, industrial automation, and machinery positioning systems.

Machine Tools: In machine tools such as milling machines, lathes, and drilling machines, spur gear racks are employed for precise movement and positioning of cutting tools or workpieces. The linear motion provided by the rack enables controlled and accurate machining operations, contributing to the overall performance and quality of the machined parts.

Automation and Robotics: Spur gear racks are widely used in automation and robotics systems. They facilitate linear motion for the movement of robotic arms, conveyors, and other automated mechanisms. The precise and controlled motion offered by spur gear racks is instrumental in achieving accurate and repeatable operations in automated processes.

Industrial Machinery: Spur gear racks find applications in various industrial machinery, including packaging machines, printing presses, textile machinery, material handling systems, and more. They contribute to the efficient and reliable operation of these machines by providing linear motion, power transmission, and precise positioning capabilities.

Overall, spur gear racks play a vital role in machinery, enabling linear motion, precise positioning, power transmission, and automation. Their versatility and reliability make them a fundamental component in numerous applications across diverse industries.

editor by CX 2023-09-25